Commitment to Quality

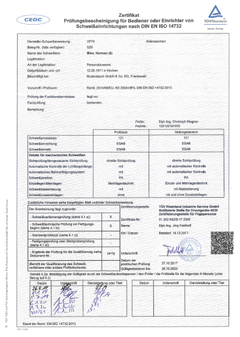

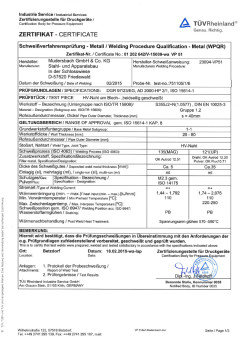

We work according to the current standards of the metal industry, which is documented by certificates. In addition, we have a very high quality standard, which runs like a red thread through the entire company and all production processes.

We guarantee the consistently high quality of our products first and foremost through quality-conscious employees and their self-monitoring. Further meticulous quality checks are carried out by master craftsmen, technicians and engineers. Standardised dimensional protocols are available for standard products such as cones, tubes, etc. Quality of the highest precision combined with low administrative costs is also reflected in the price. To your advantage.