The expert manufacturer of cones and transitions

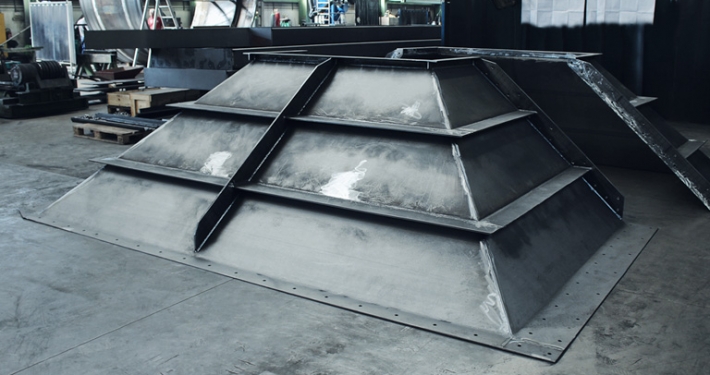

Mudersbach GmbH und Co. KG fabricates an unlimited variety of cones and joining elements transitioning from small to large, from round to rectangular, oval, concentric, eccentric, symmetric or asymmetric – flanged or extruded. Or both. Years of expertise, innovation, quality and solution-oriented thinking are crucial for a company declaring itself an expert manufacturer of cones and transitions. And our solutions fit perfectly!

Cones and transition pieces in any material thickness and quality

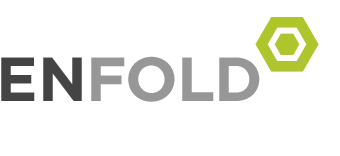

Cones are mostly shaped like a frustum with varying diameters and are often referred to as reducers. Due to their shape, they are ideally suited as joining elements (transitions) between two pipes, hollow bodies etc. with different dimensions.

Cones can be manufactured using various processing methods. Our versatile machinery includes press brakes and roll benders that we use to fabricate single items made of structural steel, boiler-quality steel plates, rustproof and heat-resistant steel with diameters of up to 6,000 mm and wall thicknesses of 3 to 150 mm. Besides cones and transitions, we also manufacture half-shells and any kind of rolled part.

Machines used by this business unit

Press brakes:

Maximum working length: 15,400 mm for virtually any material type and thickness

Sheet metal bending machines:

Maximum working length: 4,000 mm for up to 300 mm thick materials

Weld prefabrication machines:

High-performance edge sander; 25 mm milling machines; long seam milling machine used for preparing u-joints; several power tools

Highest precision and reliability in metal forming technology – just in time.

We maintain a high level of quality and precision throughout the production process, e.g. when connecting and welding the longitudinal and circumferential seams of a cone or transition. We apply various welding techniques, e.g. SAW, MAG, MMAW and GTAW, and adhere to the standards described in the Bulletin HP 0 by the German Working Committee for Pressure Vessels (Arbeitsgemeinschaft Druckbehälter, AD) and DIN EN ISO 3834-2 as well as DIN EN 1090 EXC4.

If a component is too large to be transported in one piece, Mudersbach manufactures the individual parts, e.g. two half-shells, if technically feasible, and then assembles the final product on-site.

Support by Mudersbach

If you have any questions about our range of services or a project enquiry on this topic, please do not hesitate to contact us.