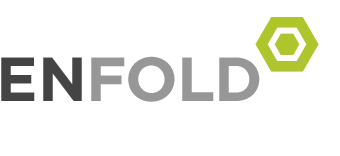

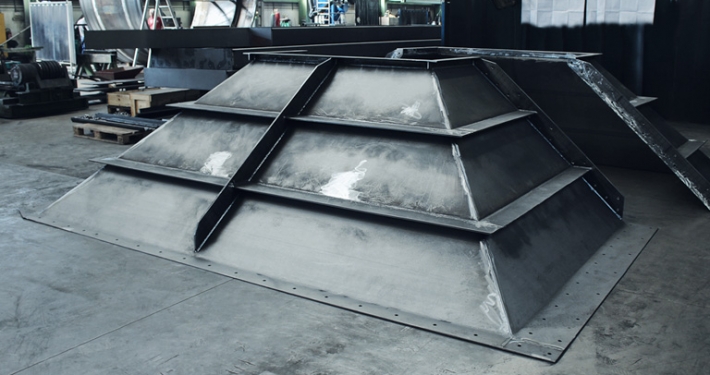

Superior, large-scale steel and welded assemblies

The manufacture of large parts requires utmost safety and precision. Mudersbach GmbH & Co. KG can fabricate individual components for machines and plants weighing up to 110 t based on customer specifications or existing CAD designs. Every day the team tackles new challenges, no matter how specific or unique, for a wide range of industries. If an assembly is too large to be transported in one piece, Mudersbach manufactures the individual components, if technically feasible, and then assembles the final product on-site.

Thanks to the experience of our employees, we face new challenges every day and master even difficult, demanding tasks in the processing of large-format sheet metal, such as the manufacture of thick-walled welded structures and large components. Optimal process sequences in the majority production, adapted to your requirements, ensure perfect results and a high life cycle of our sheet metal and steel products.

Transporting heavy equipment

Besides our own vehicle fleet, which we use for deliveries within our local trading area, we collaborate with a pool of renowned cargo carriers who handle long-distance shipments.

These are experienced carriers who specialise in the organisation and fulfilment of large shipments. Equipment is generally shipped ex works. Please contact us if you have any questions.

Demanding steel and welded constructions in large format!

We adhere to strict quality criteria that meet our customers’ requirements and our own internal standards. The company is authorised to transfer the marking of materials and products for units that require monitoring according to Sec. 1 of the German Equipment Safety Law (Geräteschutzgesetz, GSG). Manufacturing processes conform to the EN 1090 EXC 4 (Execution Class 4) welders’ certificate.

Support by Mudersbach

f you have any questions about our range of services or a project enquiry on this topic, please do not hesitate to contact us.