From individual components to complete assemblies your specialist for welded assemblies, vessels and equipment

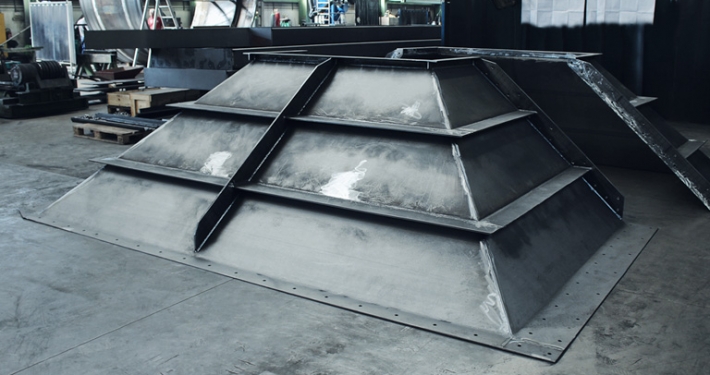

In this particular business area, Mudersbach serves mainly as a subcontractor to its business partners. We fabricate vessel components (e.g. pipe sections and cones) for designated process vessel manufacturers. Despite our technical capabilities, we are not a competitor but rather a trustworthy cooperator.

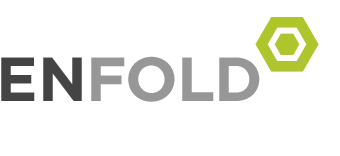

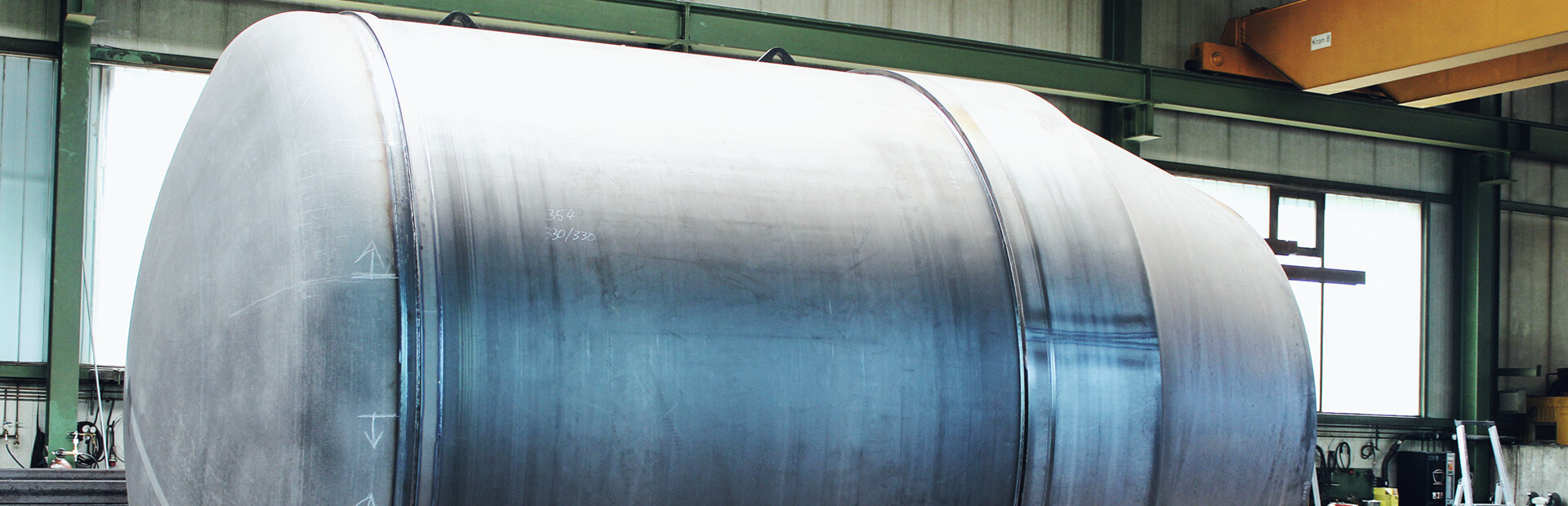

We also devise individual vessels and appliances made of steel, stainless steel and other weldable materials with wall thicknesses of 3 to 170 mm and diameters of up to 7,000 mm. Welds are realised using different submerged arc welding methods (e.g. single wire, twin wires or tandem wires) and withstand all standard procedure tests. We manufacture vessels in full accordance with the Bulletins of the German Working Committee for Pressure Vessels (Arbeitsgemeinschaft Druckbehälter, AD) and the Federal Water Act (Wasserhaushaltsgesetz, WHG), based on your drafts or our own design specifications. Larger assemblies are manufactured exclusively to customers’ specifications.

Process vessels and equipment by Mudersbach conform to the highest technical standards

Pressure vessels and equipment made by Mudersbach meet the highest technical standards and are used in many industries and manufacturing processes. Requirements can vary depending on the industry or project:

- Conical or cylindrical

- Single or multi-walled

- With or without surface treatment (coating, galvanising etc.)

- Upright or horizontal

The fact that we offer such a wide variety of services means that we can offer you exceedingly cost-effective solutions: Not only do we weld and assemble vessels and related equipment, we also cut the necessary sheet metal components. One source means fast delivery, consistent quality and reduced costs. Solutions tailored to your exact needs.

With 6,600 sqm production space and crane capacities of up to 100 t, there is virtually no limit to the size of vessels and appliances that we can manufacture. If it fits through the doors of our production hall, we can make it! It’s as simple as that. Assemblies that are too large to be transported in one piece can be fabricated as single components. The final plant is then assembled by us on-site.

Machines used by this business unit

Plate shears:

Maximum working length: 6,000 mm for up to 25 mm thick materials

Press brakes:

Maximum working length: 15,400 mm for virtually any material thickness

Sheet metal bending machines:

Maximum working length: 4,000 mm for up to 50 mm thick materials

Welding turning rolls:

Up to 70,000 kg

Welding positioners:

Up to 20,000 kg

Welding machines:

For SAW, GTAW, MAG, impulse, MMAW

Process vessels and equipment construction in any dimension

With 6,600 sqm production space and crane capacities of up to 100 t, there is virtually no limit to the size of vessels and appliances that we can manufacture. If it fits through the doors of our production hall, we can make it! It’s as simple as that. Assemblies that are too large to be transported in one piece can be fabricated as single components. The final plant is then assembled by us on-site.

Support by Mudersbach

If you have any questions about our range of services or a project enquiry on this topic, please do not hesitate to contact us.