Accurate cuts. Perfect shapes. A matter of course.

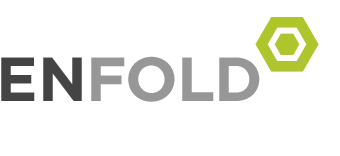

Rolling, or circular bending, requires utmost precision across all process steps. Like in folding, with this swarf-free sheet metal forming method, the material is shaped by exerting mechanical force. The ideal roll bender for a particular job depends on its diameter as well as the material thickness and material quality. For vessel sheet metal and rolled parts, for instance, we use hydraulic three-roller sheet metal bending machines. CNC controls provide additional flexibility for more unique and creative shapes.

Rolling parts and round bending of sheet metal

When flattening sheet metal, a component is reworked by targeted, minimal bending and optimized to a straight sheet metal. If necessary, flame straightening is also used. This process is also known as round bending.

Shearing of sheet metal

Metal sheets are clamped between a fixed and a moving blade and sheared across their entire length in one step. Mudersbach has two plate shears with different material grades and cut geometries, a working length of up to 6,000 mm and support for metal thicknesses of up to 25 mm.

Machines used by this business unit

Sheet metal bending machines:

15 different machines with a working length of up to 4.000 mm

Plate shears:

Maximum working length: 6,000 mm for up to 25 mm thick materials

Weld prefabrication machines:

High-performance edge sander; up to 25 mm milling machines

The perfect solution for every project

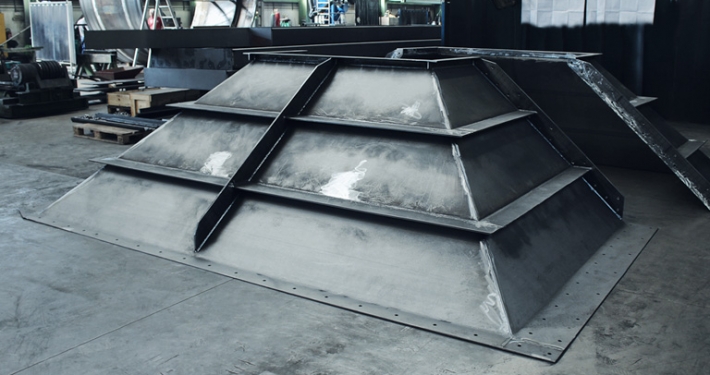

We have 15 different roll benders that we use to manufacture rolled sheet metal products to your specifications or individual parts for larger assemblies. We have the right technology for any job, incl. machines with a 1,000 to 4.000 mm worktop and an upper roller diameter of 16 to 840 mm. Almost all of these bending machines include a cone-rolling attachment.

Our production team can fabricate vessel casings, rings, cones and half-shells with exactly specified radiuses. These products can be made of different types of materials with a wall thickness of up to 300 mm.

Support by Mudersbach

If you have any questions about our range of services or a project enquiry on this topic, please do not hesitate to contact us.