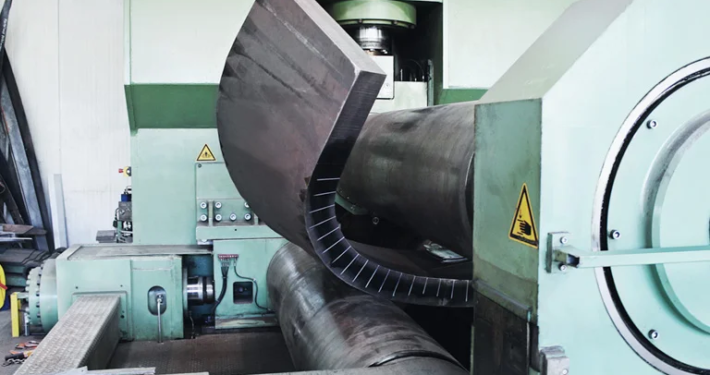

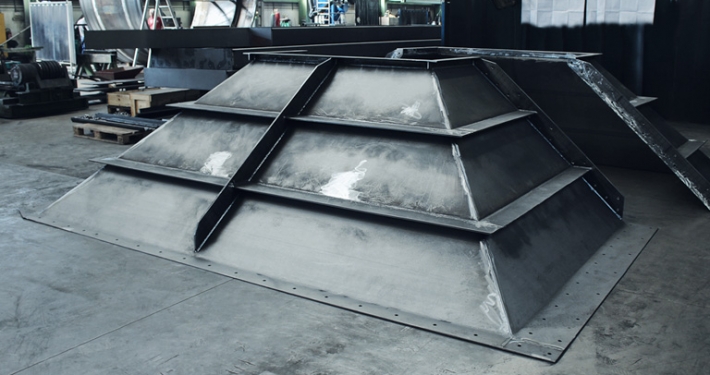

We maintain a high level of quality and precision throughout the production process, e.g. when connecting and welding the longitudinal and circumferential seams of a cone or transition. We apply various welding techniques, e.g. SAW, MAG, MMAW and GTAW, and adhere to the standards described in the Bulletin HP 0 by the German Working Committee for Pressure Vessels (Arbeitsgemeinschaft Druckbehälter, AD) and DIN EN ISO 3834-2 as well as DIN EN 1090 EXC4.

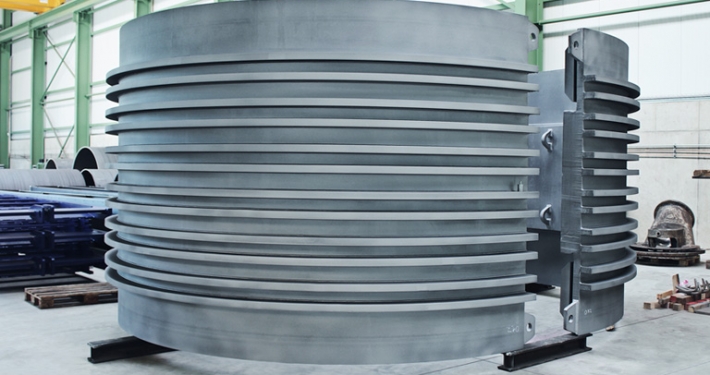

If a component is too large to be transported in one piece, Mudersbach manufactures the individual parts, e.g. two half-shells, if technically feasible, and then assembles the final product on-site.