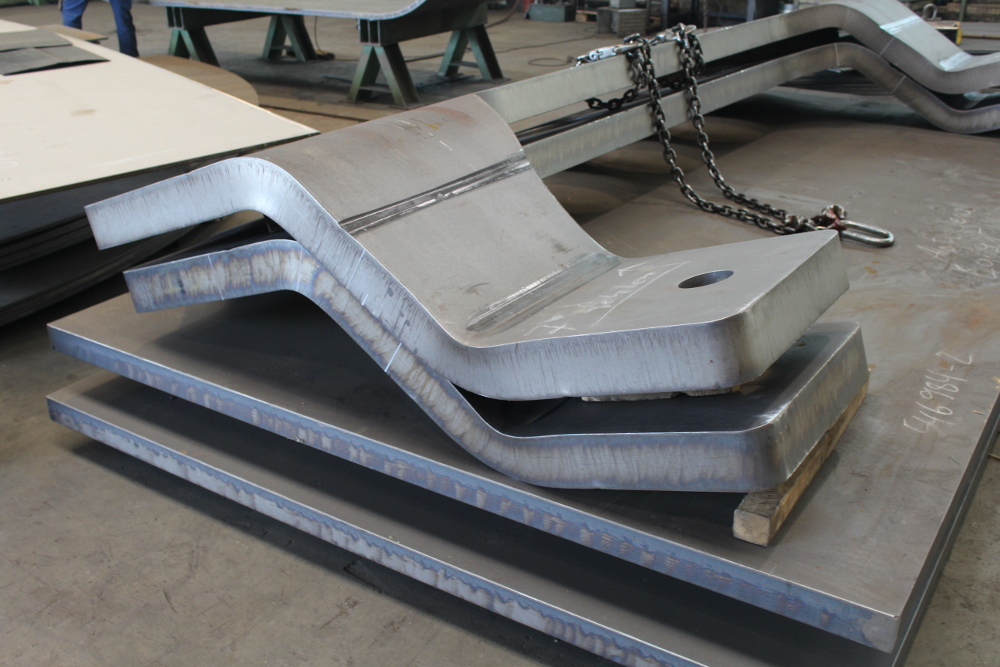

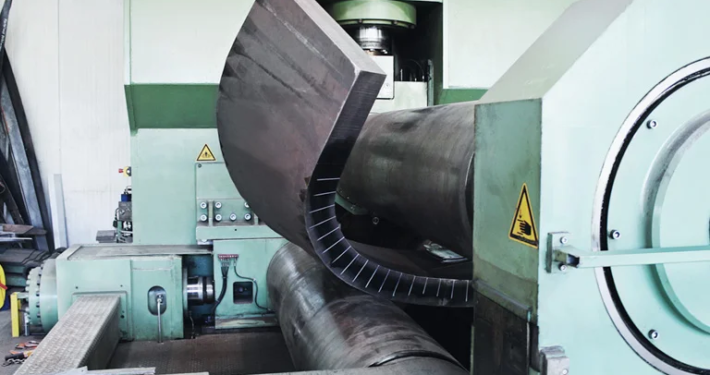

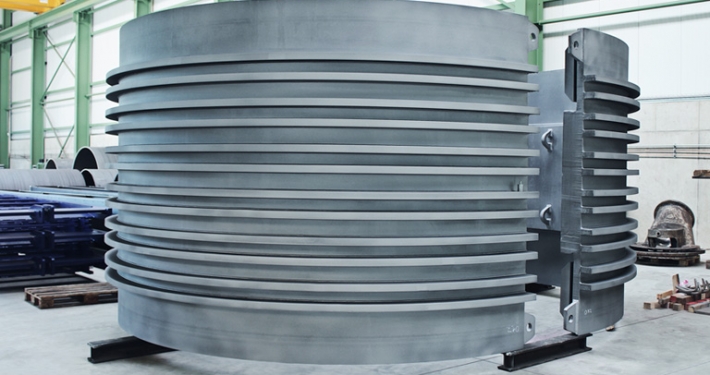

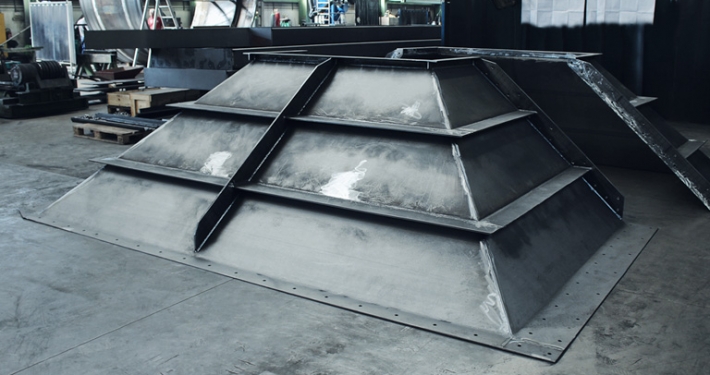

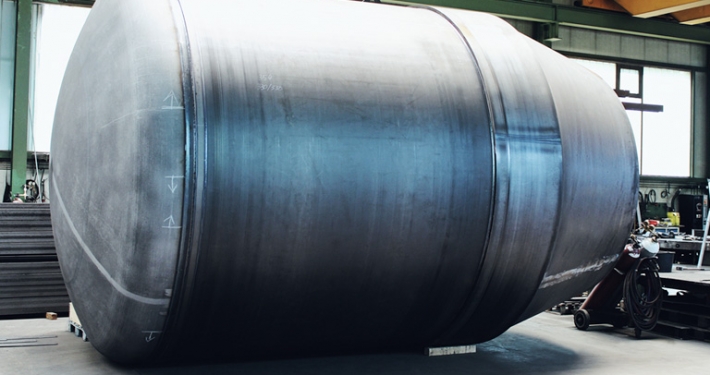

Folding of sheet metal

Individual, precise and cost-saving

Custom, precise and cost-efficient sheet metal folding up to 15,400 mm length and 150 mm thickness using advanced CNC press brakes-tailored solutions for diverse industries, delivered swiftly.